Block making in Saanganer

According to the 2008 census, 152 block carving units exist in Saanganer. Very special and interesting terminology is used in these units, words that one does not find in everyday language. It seems that the printers have developed their own language, which is important to understand, to be able to work with them. Let us look at some of these words.

A block maker or a carpenter who specializes in block making is called “Bhatt-ghar“- in Rajasthan. Here Bhatt implies block and the ghar implies the carver. The block printers of Saanganer get most of their blocks made in Purani Basti in Jaipur. Those blocks that need some special technical input are usually sent to Farukhabaad, Sitapur, Meerut or Pilakuan in UP or Pethapur in Gujarat.

Motifs of Saanganer

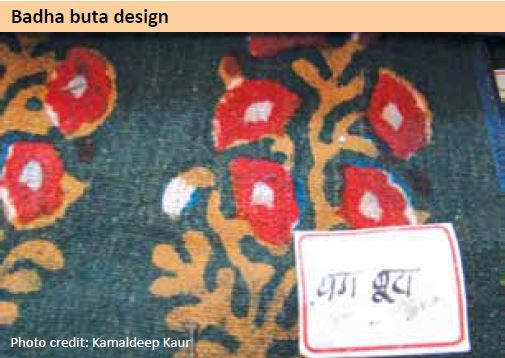

Finesse in flowers-petal designs, curves and delicacy are the prime specialties of Saanganer prints. The curvature of flowers in the ’bootas’ is generally shown on the right side. Different types of floral patterns are displayed in the form of a ‘bel’ (a border), in a stylized manner.

Some of the flowers used in the prints are roses, rosettes, lotuses, lotus bud, sunflower, lily, ‘champa’ ‘canna’ ‘nergis’, marigold etc. Various other flower creations are also found in old Saanganeri prints. Other flowers used are locally known as ‘sosan’, ‘gainda’, ‘gulmehendi’, ‘javakusum’, ‘guldaudi’, ‘kachnar’, ‘jatadari lily’, ‘kaner’, ‘kanna’, ‘gullalla’, ‘Sosan’ and ‘gullala’ prints are probably very suitable to Saanganeri style of printing, therefore they are used in various forms.

In ‘booties’, generally, only one type of flower-petal and bud creations is found; for example: ‘Badaam, (almond)’, ‘Paan’ (beetle leaf), ‘mukut of ‘kalanga’. While printing a sari, if the ‘booti’ is of ‘sosan’ flower then the ‘bel’ will also be of ‘sosan’ flower and a big ’boota’ of the same flower is usually done on the ‘Pallav’ (the decorative edge of the sari, which is displayed by the women, and left hanging from the shoulders ). Hence, for printing one sari, a large number of blocks need to be made. By printing different booties together, the Saanganeri ‘Cheepas’ have portrayed excellent know how. Sometimes more than three flowers are fitted beautifully in a single ‘booti’ e.g. in ‘Latkan booti’ banana tree, sosan tree and saro tree collection in assembled beautifully in one pattern. The designs are named accordingto the flowers or plant pattern, from which the designs were originally inspired.

Many flowers used in Saanganeri prints don’t originate from Rajasthan. On this basis, Historian James watt has said, “Obviously many of the Saanganeri designs portray flowers that in not likely to have been seen by the calico printers nor by the block engravers of Rajputana. In spite of these circumstances, however, there seems every reason to believe that the craft has been handed down for centuries and has come to be used in all the purity of original inspiration. The nature, feeling and colour reciprocity, as also the technique in printing are all perfect while the absence of machine regularity gives a charm that place these goods above and beyond anything as yet accomplished in Europe.” Apart from flowers, fruit trees of banana, dates, grapes pomegranate etc. have also been recreated in a very attractive manner. In some old prints figures of parrots and fish are also seen. Since about fifty years, elephant. Horse, camel, peacock and human figures are also used. These are mostly seen on curtains, bedcovers, table clothes etc.

Motifs of Bagru

The historical progress of the motifs of Bagru is difficult to understand. These are mostly derived from the flora and fauna and are natural in origin. A Comparative study of the evolution and layout of motifs clearly reveal a change from old tradition and style. Initially the prints were primarily floral and vegetative. After the Persian influence they became more geometrical, for example one often finds a central round and then motifs are placed around it. The motifs of Bagru may be classified into five types:

- Motifs of flowers and birds: These are often found in the stem or in the central motives which helps to balance the floral arrangement.

- Motifs of inter-twisted tendrils: These are motifs of flowers comprising of spiralled or inter-twisted stems, with flowers, leaves or birds present on the same. These are used as ‘bels’.

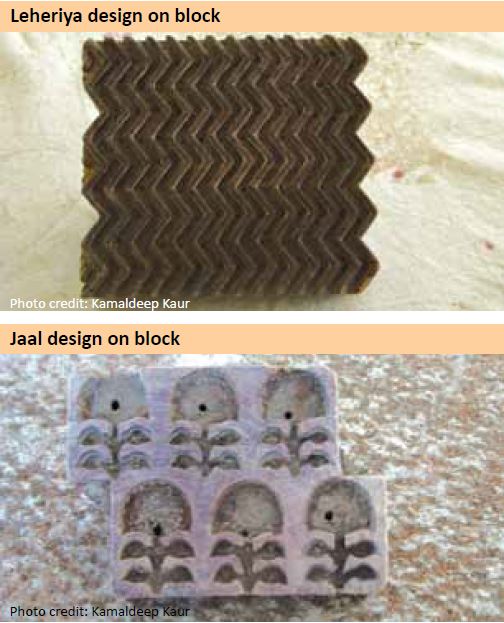

- Motifs of trellis designs: These are mainly the ‘Jaal’ intricate grid (connecting designs), which were formulated under the Persian influence.

- Motifs of figurative designs: These are animal, bird and human motifs, e.g., ‘hiran’ (deer), mayur’ (peacock), ‘sua’ (parrot).

- Motifs of geometrical designs: These are geometrical in shapes, e.g. ‘Leheriya’ (wave), ‘chaupad’ (check), ‘kanguras’ (triangular), ‘chatais’ (woven) pattern etc.

Difference between Saanganeri and Bagru style of printing

The main distinguishing feature between Saanganer and Bagru printing is that Saanganer print is usually done on a white ground, whereas Bagru prints are printed on an Indigo or a dyed background. Local water also has its effects. In the water of Saanganer, the results of block printing are very rich dark shades of colour, while at Bagru one finds a reddish tinge in the block printed textiles. Water was (intentionally being used in the past tense) abundant in Saanganer; due to which dyeing, printing as well as washing could be done very easily. In contrast at Bagru, where water

is comparatively scarce, ‘Dhabu’ resist printing and indigo work is practised more often.

Traditionally, motifs printed at Bagru are large with bold lines, as compared to Saanganer, where sombre colours and fine lines, intricate detailing are practiced. Saanganeri motifs are based on nature, while the motifs of Bagru are more often geometric.

Blocks have been used in many ways

Till 50 years back most of the fabrics that were being printed were quite coarse and thick cottons, usually handwoven. The printer often women or older men were sitting on the floor usually outside the house and printing during the day time, when they became free from their house hold work.

They printed on very small low tables called the “Paatiya”.

The blocks used were quite small in size. Once a small portion of the fabric was printed the printer very carefully moved the fabric forward. Due to the thickness of the fabric it was easier to restart printing without any difficulty, exactly where one had stopped.

A point to note here is that if a bigger block would have been used, instead of a tiny block, then the printing would have been done in less than half the time. But the fabric would still be wet with the colour, and thus when it was moved the wet colours would have left spots. Thus it was necessary to use small blocks on the small tables.

In the finer fabrics used today, it is impossible to move the fabric during printing. Thus one must use bigger tables where there is no need to move the fabric during the printing process. In present times, the fabric is fixed with oil pins, on to the table and the printer moves with a trolley having colours and other tools.

In some villages in Kutch when printers print with wax using blocks, they still print on the Paatiya. The wax is very hot when it is printed. The printer keeps dipping his block in the hot boiling wax, close to him, and keeps printing. They often use bigger blocks in this case, as the main product being printed is bedspreads which have a big central medallion. Thus the portion of fabric on the table gets printed quite quickly, but at the same time it dries very quickly as well. What is interesting here is that the table is covered with sand before being covered with the fabric to be printed. The sand being cold dries the wax immediately.

Thus, much technical knowledge is required along with experience, when deciding the kind and size of blocks that can be used in a particular situation. It is not only the low table there is more science to deciding the size of the blocks. There are many factors that one needs to consider, like the printing style, the fabric and so on.

Among the technical differences what seems interesting is the Thassa. Saanganer printers with their history of 450 years of block printing often used these kinds of blocks. The blocks generally were carved out of soft but strong wood called Gurjan, Instead of the block being carved completely, the fine portions were actually created by forcing a piece of metal inside them, which was carved in the shape of the very pattern that needed to be created in the empty space. This formulation of blocks was called “Thassa” (which means pressed). These blocks generally had booti, boota, jaal, pharcha (borders) motifs which were not more than 6”x 6” in size. There were blocks which were 1”x 2” in size too. Saanganer prints were generally for the royalties of Jaipur.11

The same approach towards blocks can be traced back in Germany, in the famous “Blaudruck” technique. Which is basically blue (indigo) printing using resist, there are still a few printers left across Germany who practise the same technique. Initially blocks were made in the same way as a wood cut would be engraved. It was probably around the beginning of the 18th century, that the need for perfection increased considerably. As a result, the blocks were perforated by brass pins and strips driven into them. These strips were shaped as leaves or petals of flowers which were too fine to be cut. Sometimes they were also used to create geometric designs also. Thus a block is not just a carved piece of wood, it can have many additions or subtractions made by the intelligent block makers and printers according to their immediate requirements.12

12 Fairy fancy on fabrics –Erwin Bindewald Karl kasper

Features of blocks

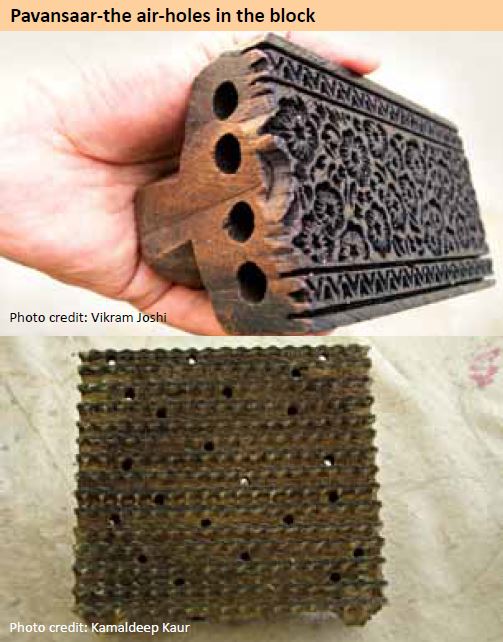

It may be surprising to learn that wooden blocks can have so many characters. But an art that has evolved over centuries it does have many minutiae. “Pavansaar” is an innovation introduced to facilitate printing. These are basically holes created in the blocks so that air “pavan” can pass through and the block does not get blocked. These blocks also had holes drilled along and across the grains of wood to stop colour from getting trapped in the fine carved area because of capillary action and help in the maintaining the block as well the design that’s printed. This means that due to the presence of holes colour does not spread on the fabric while printing. The holes also reduce the weight of the block.

For Abhrak printing, the blocks have a cylindrical hollow made entirely of copper. Rogan paste is filled inside these hollow cylinders. The design is made in the hollow metal cylindrical block and then transferred on to the fabric with the help of a wooden mallet. The wooden mallet is the same shape as the hollow cylinder. Gold, silver or copper dust is than spread onto the wet paste, extra dust is brushed off after a while. Outside India this technique was used to copy gold embroidered or woven Damask fabrics. A velvet effect was similarly used by printing some kind of gum and then spreading fine woollen powder on the same.13

Blocks for embroidery

Blocks have also been used for embroidery. Kashmiri shawls, for instance, which have extremely fine paisley designs have corresponding fine blocks which are used to print embroidery designs. In the past it was very common in various crafts like baandhani or embroidery to use blocks instead of tracing the design by a tracing paper. The blocks were meticulously printed using Multaani mitti on the surface of the fabric. The mud gave a fugitive yellow colour. The next step was to start embroidery on the shawl based on these prints.

The same method of tracing pattern by blocks was used in Baandhani techniques in Gujarat and Rajasthan. In fact it is still very commonly used for the traditional designs, as blocks have a much longer life than tracing papers. In Gujarat, instead of Multani mitti, Geru (a red coloured earth) was used for printing the design on fabric. Later on it was replaced by fugitive synthetic indigo powder, Neel, which is commonly used in India on white clothing, to maintain the whiteness of the fabric.

Blocks used in printing of designs for baandhani in Gujarat and Rajasthan

Kashmir – block design for yoke of a women’s dress, Once the design is printed using the block, then the embroidery commences

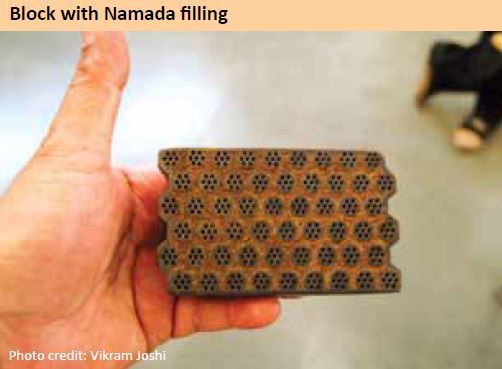

A special feature of Gujarat and Rajasthan (especially Saanganer and Bagru) was the use of Namada- Felt, for the absorption of colours in a uniform way from the printing container. The thick and thin part of carved area sometimes makes it difficult for the printer to take the colours uniformly from the printing tray, so the felt acts like blotting paper to absorb the colour and transfer it onto the fabric.

To get very fine patterns often metal was used in the outline area or the outline block. It is also common to find nails of a wide variety of sizes used to create fine dots. These are usually created to fill the empty space in between floral designs.

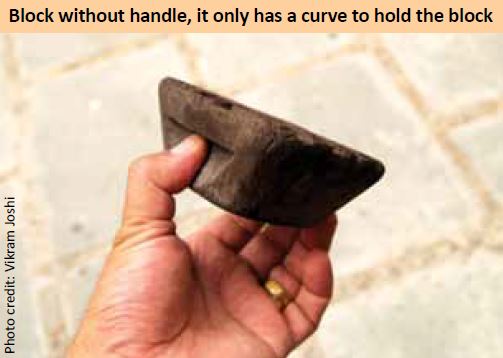

Another place where one finds innovation is the handle created to hold the block. About hundred years back it was quite common to find blocks and the handle of the block carved out of one single piece of wood. These blocks took a large space to store. Blocks found in Pipaad, Jodhpur, Samdaari and Balotra had a special feature, that the handles were removed, when the blocks were not in use. These blocks were carved out of a special wood called Royada and were also very light weight.14

14 Vikram Joshi

Leave a Reply